Don’t test in prod. Use digital twins for safer, smarter resilience

Bill Reid

Security Advisor, Office of the CISO

Sri Gourisetti

Senior Cybersecurity Advisor, Office of the CISO

Hear monthly from our Cloud CISO in your inbox

Get the latest on security from Cloud CISO Phil Venables.

SubscribeFilmmakers have relied on stunt doubles for more than a century to take the fall, get blown up, and perform all manner of dangerous tasks to keep actors safe from harm. Similarly, the IT industry has developed its own version of a stunt double to keep systems safe from harm: the digital twin, your IT stunt double.

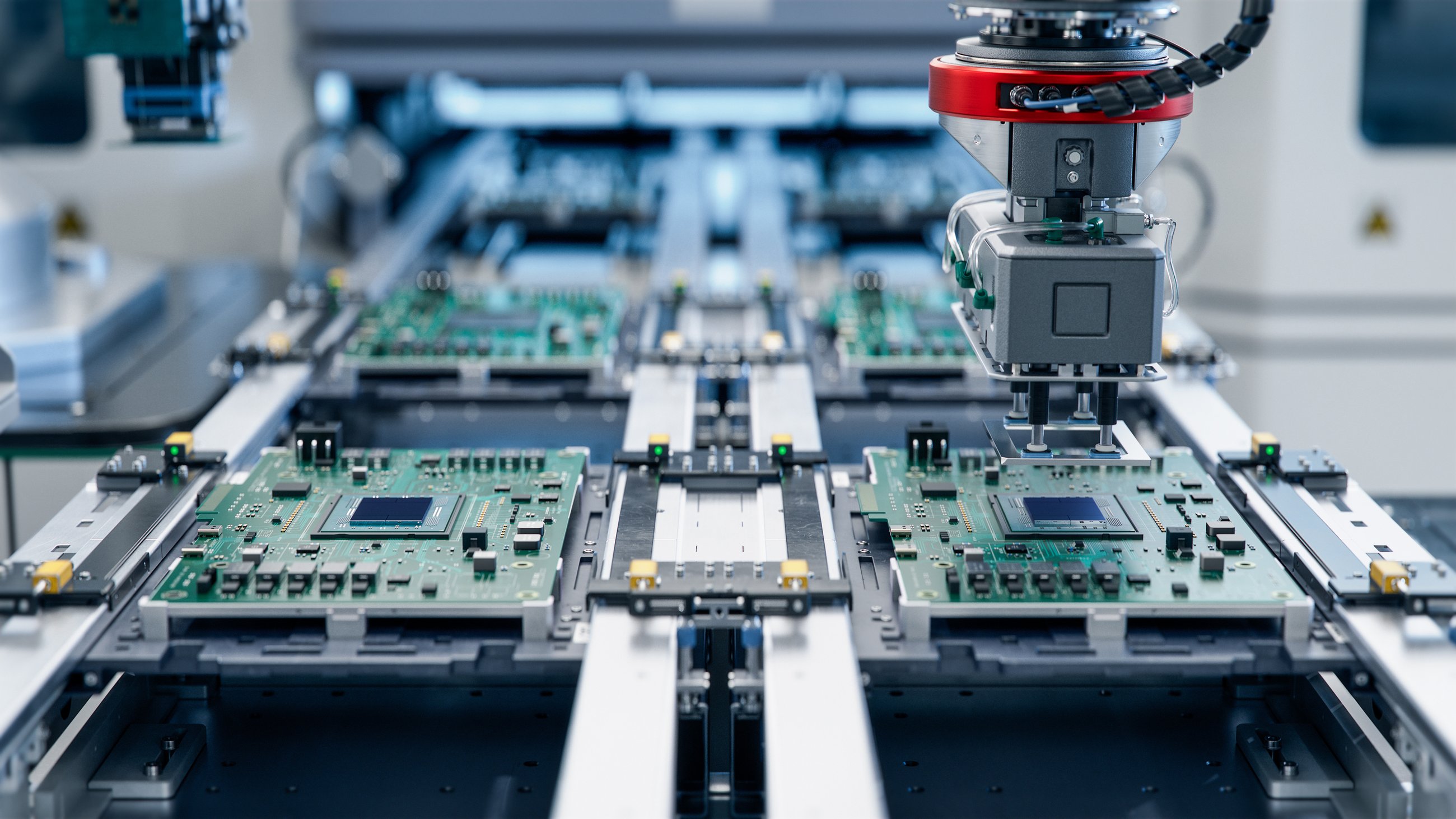

Digital twins are functional digital replicas of physical systems using real-time data, and they offer a solution by providing a safe environment for security and resilience testing. Digital twins can help with the process of securing many cyber-physical systems, allowing organizations to test process and system changes, software patches, and more without having to worry about causing real harm or disruption to critical production systems and business processes if things don’t go as planned.

In short, digital twinning can help organizations become more resilient.

“Cyber-physical resilience is the capacity of an integrated system to keep running — even if not at peak performance — should it lose specific functions. Challenges include degradation or cessation of one or more aspects of the computational or physical functions due to component failures, human errors, natural disasters, or malicious attacks,” wrote Phil Venables, strategic security adviser, Google Cloud, in the PCAST report.

The core concept of cyber-physical resilience of a system boils down to a single question: Can minimum-required resources for the business to operate flow as intended when under threat?

The challenge in creating a digital twin is how to adequately replicate physical machines and processes in a digital environment. To do this, we need to find a way to measure the performance of those machines, and represent them digitally.

How digital twins keeps workers and the business safe

To design functional digital twins, you should combine digital and physical measurements. We then mathematically compare these replicas to the physical system to see how accurately they have been approximated, working to refine a high-fidelity digital twin system.

The next step is to choose appropriate cyber-physical resilience metrics. Applied to the twin, these metrics can evaluate the level of resiliency likely present in the physical systems, which allows us to conduct low-risk tests that would not be safe or allowable on the physical system.

The systems in industrial and operational environments are in place to serve the production process, from producing a tangible product to generating electricity. Many of these systems exist as part of validated or controlled environments, or governed by regulatory guardrails.

Digital twins bring a powerful capability to security organizations, especially those managing risks in operational environments that must keep running and are too expensive to physically replicate.

Performing real-time resilience analysis on these systems while in a production process is nontrivial and dangerous. Most businesses simply cannot take the risk of safety and production issues from shutting down the process leading to economic, trust, and reputational impacts.

This is where the digital twin magic occurs. Safer tests help us better understand the physical systems’ weaknesses and subsequently validate controls that enhance resilience.

Building a digital twin takes allies (lots of them)

As a CISO, you will need to find organizational allies, identify and develop talent, and implement the tooling that allows the twin to be built and operated.

Important allies include the heads of the manufacturing and production processes being modeled. They will need to understand the value brought by twinning, and what will be required to be able to use the data from their production environments. If this is a regulated process, allies will also include the quality officer who will need to understand the system impacts of adding measurement tools and approve these changes.

Crucially, the CIO and CTO will likely set up the environment and maintain it. Each of these owners will want to know the budget and operational impact.

Identifying the best talent to build and use the digital twin is vital and potentially challenging. While digital twinning is becoming more common, it’s still unusual for manufacturing and critical infrastructure organizations to take advantage of it.

Given its novelty, the CISO will need to identify the right mix of talent to build and use the twin. This should include engineers who understand the operational technology and the associated production processes, IT staff who can build the digital environment to host the twin, and security engineers who can translate the metrics into the twinned system. It may also require data scientists who can construct relevant models from operational data.

Choosing the right tools presents its own challenges because the digital twin is more than a simulation of a physical system. Rather than a static point-in-time, the digital twin gets its power from replicating an operational environment that you can concurrently feed operational data.

Digital twins can use cloud infrastructure for secure networking of on-premises systems to the virtual private cloud (VPC), and multiple storage and compute options to accommodate different types of data. AI modeling services will be needed to understand the operational data. To translate the metrics into resiliency measures, you will need application development tools.

How to make digital twinning happen

Digital twins bring a powerful capability to security organizations, especially those managing risks in operational environments that must keep running and are too expensive to physically replicate.

Google Cloud is partnering with a number of customers across the manufacturing and industrial sectors to strategize around digital twins and engineer scalable twins. As security teams take on a starring role in improving the resilience of their organizations, they will, like any star in an action thriller, benefit by having a stunt double alongside to help it all look easier. Much better to have the twin take the fall than the operating business.

To learn more about how to develop a digital twin for your organization using Google Cloud, please read our companion blog.